|

Zambia Sugar – Nakambala 2015 |

| |

Part of the M1 Project was the manufacture , pre assemble and supply was a 85 m3 “A” Continuous Vacuum Pan (CVP).

The weight of this section of the project was about 67 tons.

The CVP was transported to location in two section , via abnormal loads to be assembled on site.

_____ _____

_____ _____

|

|

Zambia Sugar – Nakambala 2015 |

| |

The supply for the design, drawing, manufacture and deliver to site of process and storage tanks.Tanks delivered so far:

B Molasses Tank

Jet 2 Tank

No 2 Vacuum pump seal tank

Mud filter vacuum seal tank

Refinery mixing tank

Refinery vacuum seal tank |

Jet 1 tank

Jet 3 tank

MOL Dosing tank

R1, R2, R3 Pan feed tanks

Refinery process water tank

Sweet water tank |

_____ _____

|

|

Zambia Sugar – Nakambala 2015 |

| |

The first two of four Juice Heaters ready to leave for Zambia.

Design Code PD 5500 Category 2/3 Weight 14 tons.

_____ _____

|

|

Zambia Sugar – Nakambala 2015 |

| |

One Impure Condensate Vessel left for Zambia Sugar – Nakambala Mill this week.

Made from Mild steel to a design code PD 5500.

_____ _____

|

|

New equipment for Illovo/Zambia Sugar – Nakambala Sugar Mill |

| |

The first load of new equipment to leave for Illovo / Zambia Sugar – Nakambala Sugar Mill.

This load consisted of the following equipment:

1 x CVP Knock out pot ( 304 Stainless Steel)

1 x Evaporator Knock out pot (304 Stainless Steel)

1 x CVP Condenser 14.4 TPH

1 x Refinery Evaporator Condenser 5.5 TPH

1 x V1 Condensate Collection tank

_____ _____

_____ |

|

Zambia Sugar – Nakambala 2015 |

| |

The next delivery of new equipment to leave for Illovo / Zambia Sugar – Nakambala Sugar Mill.

This load consisted of the following equipment:

1 x V4 Flash vessel

1 x V3 Flash vessel

1 x Clear juice heater Condensate vessel

1 x Lime & liquor wheel

_____

_____ |

|

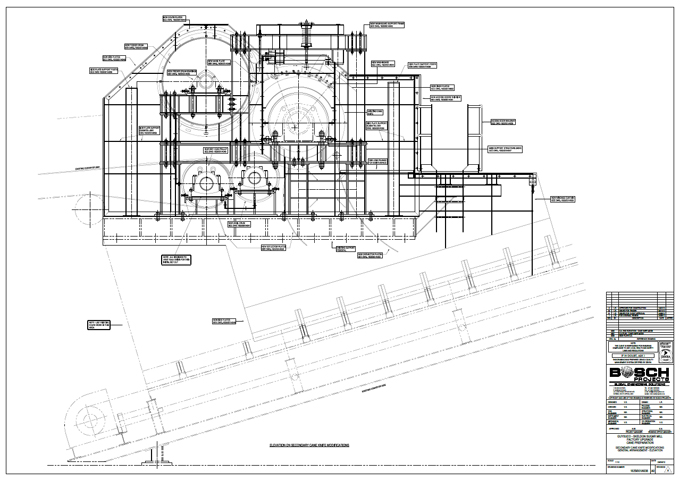

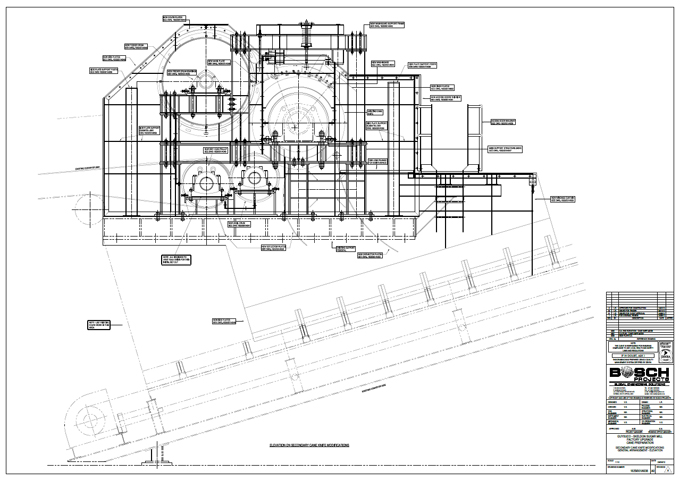

Zambia Sugar – M1 - Nakambala 2015 |

| |

The first of 26 loads of material and components for the conditioning silo.

To supply all the material prepared for site assembly - one conditioning silo shell and all structures above the concrete foundation base.

_____ _____

|

|

Press water heater: February 2015 |

The following two Press Water Heater we made for Illovo Sezela Sugar Mill.

The project included the supply, design & drawing, AIA and delivery to site.

Material – 3CR12

_____ |

|

Zambia Sugar : January 2015 |

The supply of the following equipment for Illovo – Zambia Sugar was completed in January for the 2014/15 off-crop season:

1) Chain carrier head shaft complete with sprockets

2) Diffuser scrapper drum complete with shafts.

_____ _____

|

|

Shredder Washboard – November 2014 |

A shredder washboard with breaker bars was fabricated for UCL Company Pty Limited, Dalton.

_____ |

|

Syrup Clarifier and associated equipment – November 2014 |

An order for a Syrup clarifier and associated equipment was placed with us in June 2014.

The project involved the design, drawing, manufacture, transport, installation and commission of this project at Illovo – Noodsburg Sugar Mill.

The installation took 12 weeks to commissioning.

The following equipment was supplied:

Structural Steel, flooring, access platforms and walkways.

Flash Cooler – Design Code ASME VIII

Juice Heater - Design Code ASME VIII

Syrup Buffer tank - Design Code ASME VIII

Syrup reactor tank

Phosphoric Acid Tank

Lime Sacchrate Preparation & Storage tank

Flocculant Preparation & Storage tank

Syrup Clarifier – 32m2

Pipe work to suit this project

_____

_____

_____ |

|

Shredder spares for ED Exports ____________________________________________________May 2014 |

The follow shredder spares were ordered by ED Exports for export into Africa:

One Anvil plate manufactured from mild steel with grid bars hard face.

Eight hammer rods made from SS431 (EN57) material & machined to suit.

____ _____

_________ |

|

Massecuite Reheater |

An order was placed by Illovo – Noodsburg Sugar Mill for a new “C” Massecuite Reheater. The project included the removal, installation, pipework and commissioning of the reheater.

The order was completed and installed for the Off crop 2014.

|

| |

|

|

Another Bagasse mingler with support frame was built for Illovo Sugar |

|

Ruembe Sugar Mill, complete with lifting lugs and guards. Made from Mild steel material was supplied complete with sprockets, drive chains and Motor & gearbox. Project was completed in 6 weeks. |

|

|

| |

| |

|

Cane Preparation Equipment |

|

An Order was placed by Bosch Projects for the supply of Cane Preparation Equipment for the GuySuCo project in Guyana. The following equipment was supplied , preassembled, checked and loaded in to containers as CIF.

- Conveyor head & tail pulley c/w shaft and couplings

- Conveyor gearbox, motor & coupling

- Conveyor drive bases

- Cane knifes

- Support structure

- Anvil Plates

- Take up section

- Cover & Liner plates

- Access doors

- Feeder drum c/w shaft & bearings

- Feeder drum gearbox, motor & coupling

- Windage curtain

The fabrication, painting and supply was completed in a six month period.

|

|

|

|

| |

| |

|

Scalding Juice Heater |

|

An order was placed by Tongaat Maidstone Sugar Mill part of the Tongaat Hulletts group for the removal and manufacture of a new Scalding Juice heater.

The unit was designed to a design code : BS 1500 Class 2 with an AIA inspection required.

Once the old unit had been removed the new scalding Juice heater was installed and piped up ready for commissioning. |

|

|

| |

| |

|

Heavy Duty Shedder |

|

An order was place by a local supplier to manufacture a complete shredder complete with housing. The project will be exported to Sierra one, Makeni Ethanol Co generation Plant. A complete shop fit up was done as requested by the client. The drive & gearboxes were excluded from the scope of supply.

The project consisted of the following items:

-

Feeder drum

-

Carling Drum x 2

-

Shredder rotor

-

Shredder housing

-

Anvil

-

Hammers x 352

-

Access platform & walkway

-

Conveyor chute – Top section.

|

|

|

| |

| |

|

Bagasse Mangler |

|

A Bagasse mingler with support frame was built for Illovo Sugar – Ruembe Sugar Mill, complete with lifting lugs and guards. Made from Mild steel material was supplied complete with sprockets, drive chains and Motor & gearbox. Project was completed in 6 weeks. |

|

|

| |

| |

|

Sugar Dryer Rings |

|

In the off-crop of 2012 , Illovo – Nchalo in Malawi had two Sugar Dryer rings remade from samples that had been sent to us. These items where remade F.P. Engineering high standard and in accordance with ISO 9001. These item where completed and sent to the mill prior to start up date in April |

|

|

| |

| |

| |

Ubombo 300TCH Diffuser |

| F.P. Engineering was awarded the contract to fabricate, install and commission the new chainless diffuser and ancillary equipment at Ubombo Sugar Mill – Swaziland in the new expansion project for 2010. This new project will last about 11 months from start of fabrication to final hand over in March 2011. |

|

|

| |

| |

| |

Magara Expansion Project |

F.P. Engineering was awarded the contract to design, fabricate, transport to location, Third Party Inspection and site supervise the following items that were to be installed in the Maragra Expansion Project in Mozambique 2009/2010.

This project completed in a 6 month period.

The following items were fabricated:

- 70 M3 Continuous Vacuum Pan

- 1000 M2 Roberts Type Evaporator

- Long Tube Evaporator

- 35 ton Hilo Unloader

|

|

| |

| |

| Xinavane Expansion Project |

F.P. Engineering was awarded the contract to design, fabricate, transport to location, Third Party Inspection and site supervise three 240 cubic meter “A” Crystalliser complete with drive gear boxes that where to be installed in the Xinavane Expansion Project in Mozambique 2008/2009.

The units where 5200mm in diameter and 14 m high, where sent to site as abnormal loads in donnut form. All work done on this project was completed in the workshop. |

|

| |